Tuesday,

September 12, 2006

The morning flies by quickly. Lots of cheese to salt. I asked Nick if I could help with the afternoon goat cheese today. "Of course," came is response. It's nice to be well received.

Shortly after 10:00AM, Nick utters the phrase "Well, alright. Let's go put the kettle on." We don't just take a break, we pause and refresh ourselves with a fine cuppa PG Tips for Ben and me. Green tea for Nick. I'll have to keep up this tradition when pacing my own work day.

After tea, Nick pulls out several batches of Devon Blue to prepare for wholesale orders. The mature cheese must be unwrapped from its plastic wrap skin, scraped with a knife and then wrapped in a thick gold foil. Then we put a sticker on it and put them into the fridge. When preparing orders, the foil wrapped cheese is placed into cardboard boxes and sent by refrigerator van to all points around the UK. Couriers pull up several times a day. They always wear shorts and are a nice bunch of guys. Around noon, Nick begins to make Harbourne Blue. He adds the starter culture as he's filling the smaller of the two rectangular vats with fresh goat's milk. When the vat is full, he adds a capful of liquid blue mold to the milk. He leaves it to ripen. When it's time to add the rennet, I walk over to watch. He measures out a small amount of rennet and adds it to a pitcher of water. He gently stirs the milk and quickly pours the rennet into the cultured milk. Gives it a quick stir and covers the vat to let it the rennet turn the milk into a soft jelly. We go back to scraping and wrapping mature cheese.

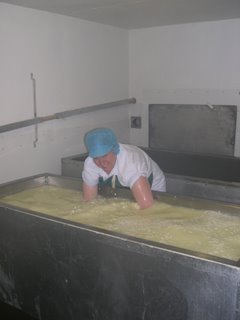

Nick keeps an eye on the clock. Time for first cut. He hands me the cheese harp. Oh boy! I cut the curds as instructed. I'm less timid this time, more sure of the motions I must use to ensure an even cut. I go back and forth, cutting the gelatinous white mass into small cubes. The whey begins to be released immediately. Once the curds are cut, the knife is set in one corner of the vat, the cover is replaced, and we wait. Time for second cut. I use more of a stirring motion with this cut, making the curds even smaller and releasing even more whey. They shrink a lot by the time they reach the moulds. Camera lens got fogged up in the humid making room. Sorry mom.

Camera lens got fogged up in the humid making room. Sorry mom.

Time to stir the curds. I roll up my sleeves, scrub up, and plunge my arms into the vat. The goat curds feel very different from cow's milk. The body is much more delicate. It feels lighter. The curds are smaller. It doesn't have the same smell, less sweet. I stir all around the vat, twice. Cover and wait. Time to stir again. I let the curd settle for a moment. We then push the curds to one end of the vat, install a semi-circular, perforated device that keeps the curd in the vat, but lets the whey out. We drain the whey and scoop the curds out of the vat and make cheese. Moulds get filled to within an inch of the top. After several moulds are filled, Nick flips one on top of another, so the contents of two moulds combine into one and drain together. After 20 minutes, they have drained and shrunken a great deal. The top mould is pulled off and the cheese in the bottom mould looks like a huge cupcake, with a large lip on top. We made about 16 Harbourne Blues today.

Thursday, September 14, 2006

Have a cuppa tea

Posted by

Sairbair

at

3:37 PM

![]()

Labels: Ticklemore Cheese Devon England

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment